Brazing Filler Metals / Alloys for Brazing Processes

Brazing is a group of joining processes that allow materials to be fused together by heating them to a brazing temperature in the presence of a brazing filler metal. This metal has a liquidus temperature above 840°F and below the solidus temperature of the base metal. The filler metal flows into the joint through capillary action, creating a strong and reliable bond.

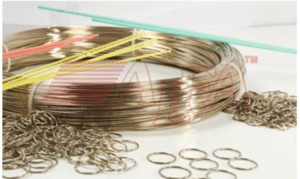

Shree Kailaji Alloys, a trusted Brazing Filler Wire Manufacturer, Supplier in India, provides a complete range of brazing alloys and fluxes for various industrial applications. Our products are designed for durability, precision, and consistent performance across multiple industries.

Our Range of Brazing Alloys

Silver Brazing Alloys With Cadmium

We offer high-quality cadmium-bearing alloys with an excellent combination of melting range, capillary flow, and mechanical strength. These alloys are cost-effective solutions where the presence of cadmium is acceptable.

Silver Brazing Alloys Without Cadmium

Understanding the needs of industries like food and beverage, we supply cadmium-free alloys suitable for most ferrous and non-ferrous metals. These are available in multiple forms, including wire, strip, powder, paste, preforms, clad tri-metal products, and flux-cored wires.

Silver Brazing Alloys for Tungsten Carbide Tipped Tools

We manufacture specialized nickel-containing brazing filler metals for tungsten carbide tipped tools. These alloys provide protection from crevice corrosion and perform well at high temperatures. Available in wire, foils, or shims, they meet stringent industrial standards.

Silver Copper Phosphorus Brazing Alloys

Our copper phosphorus alloys are perfect for refrigeration, air conditioning, and plumbing industries. They are widely used to join copper and copper alloys such as brasses and bronzes. These alloys are self-fluxing on copper and are available in wires, strips, wire flattening, preforms, granules, and spheres. Custom solutions are also provided based on your requirements.

Copper Based Brazing Alloys-Brasses And Bronzes

TWe supply general-purpose brasses, brasses with added nickel, high-temperature copper alloys, and furnace brazing copper. These alloys are economical, versatile, and can be supplied in rods, wires, preforms, strips, powders, and pastes. They are ideal for Oxy-Fuel Gas Braze-Welding processes.

Fluxes

We manufacture a wide variety of fluxes suitable for different applications. These include mild organic acids or strong inorganic acids that promote fast cleaning of metals with strong surface oxides. Our fluxes are commonly used in silver brazing, copper brazing, soldering, and aluminium welding.

Applications Mentioned

As a leading Brazing Filler Wire Manufacturer, Supplier in India, we provide brazing solutions trusted across multiple industries. Our filler wires and brazing alloys are used anywhere strong, reliable and leak-proof joints are required. Some of the major applications include:

- Refrigeration & Air-Conditioning Systems – Ideal for joining copper tubes and components.

- Automotive Components – Ensures precise, durable bonding in engines, sensors, and exhaust parts.

- Aerospace & Defense – Used for high-strength, vibration-resistant joints.

- Electrical & Electronics – Perfect for conductive and corrosion-resistant material bonding.

- Carbide Tipped Tools – Special nickel-bearing alloys for joining tungsten carbide.

- General Engineering & Fabrication – Suitable for joining ferrous and non-ferrous alloys.

Our brazing materials are designed to meet the high-performance expectations of modern manufacturing industries.

Forms Available

To make brazing easier and more efficient across different processes, we offer our filler metals in multiple forms. As a trusted Brazing Filler Wire Manufacturer, Supplier in India, we ensure consistent quality across every form:

- Wires – Standard and custom diameters

- Rods – Ideal for manual brazing

- Strips & Foils – Suitable for controlled atmosphere brazing

- Powders & Pastes – For automated and precision applications

- Shims & Preforms – Made-to-order for high-volume production

- Flux-Coated Wires – For cleaner, faster applications

- Granules & Spheres – For specific industrial requirements

Each form is available in cadmium-bearing, cadmium-free, copper-based, and specialty silver alloys.

Applications & Industries We Serve

Our brazing filler wires and alloys are widely used across:

- HVAC & Refrigeration

- Automotive & Transportation

- Aerospace & Aviation

- Electrical & Electronics Manufacturing

- Tooling & Carbide Tip Industry

- Metal Fabrication Workshops

- Heavy Engineering

- Food & Beverage Equipment Manufacturing

Each industry relies on brazing for strong, durable and corrosion-resistant joints—something our products are designed repeatedly to deliver.

Why Choose Us

Choosing the right brazing partner is essential for performance and efficiency. Here’s why industries trust us as the most reliable Brazing Filler Wire Manufacturer, Supplier in India:

✔ Wide Product Range

From silver brazing alloys to copper-phosphorus and nickel-bearing wires, we offer solutions for every brazing requirement.

✔ Consistent Quality

All products are manufactured under strict quality standards ensuring uniform melting range, strength, and flow properties

✔ Customized Solutions

Whether you need a special alloy composition or unique form like strips, shims, or flux-cored wire—we customize as per application.

✔ Industry Expertise Since 1975

Decades of experience in welding and brazing consumables make us one of India’s most trusted names.

✔ Bulk Supply & Nationwide Delivery

We deliver large volumes on time, ensuring uninterrupted production for your business.

FAQ Section

1. What is Brazing Filler Wire used for?

Brazing filler wire is used to join two metals by heating them with a filler alloy. It creates strong, leak-proof joints in refrigeration systems, automotive parts, electrical components and high-temperature applications.

2. How to choose the right brazing alloy?

Selecting the right alloy depends on the base metal, operating temperature, strength requirement, and whether flux is needed. Our experts can guide you based on your application.

3. What is the difference between cadmium and cadmium-free alloys?

Cadmium-bearing alloys offer excellent flow and cost benefits, while cadmium-free alloys are safer and suitable for food, beverage, and medical applications.

4. Do you supply Brazing Filler Wire in bulk?

Yes, we supply brazing filler wires and alloys in bulk quantities for industrial and manufacturing units across India.

5. What standards do your brazing wires follow?

Our products follow industry standards such as AWS, ISO, and BIS, ensuring consistent performance and reliability.

by

by